Transform Operations with Intelligent Compliance

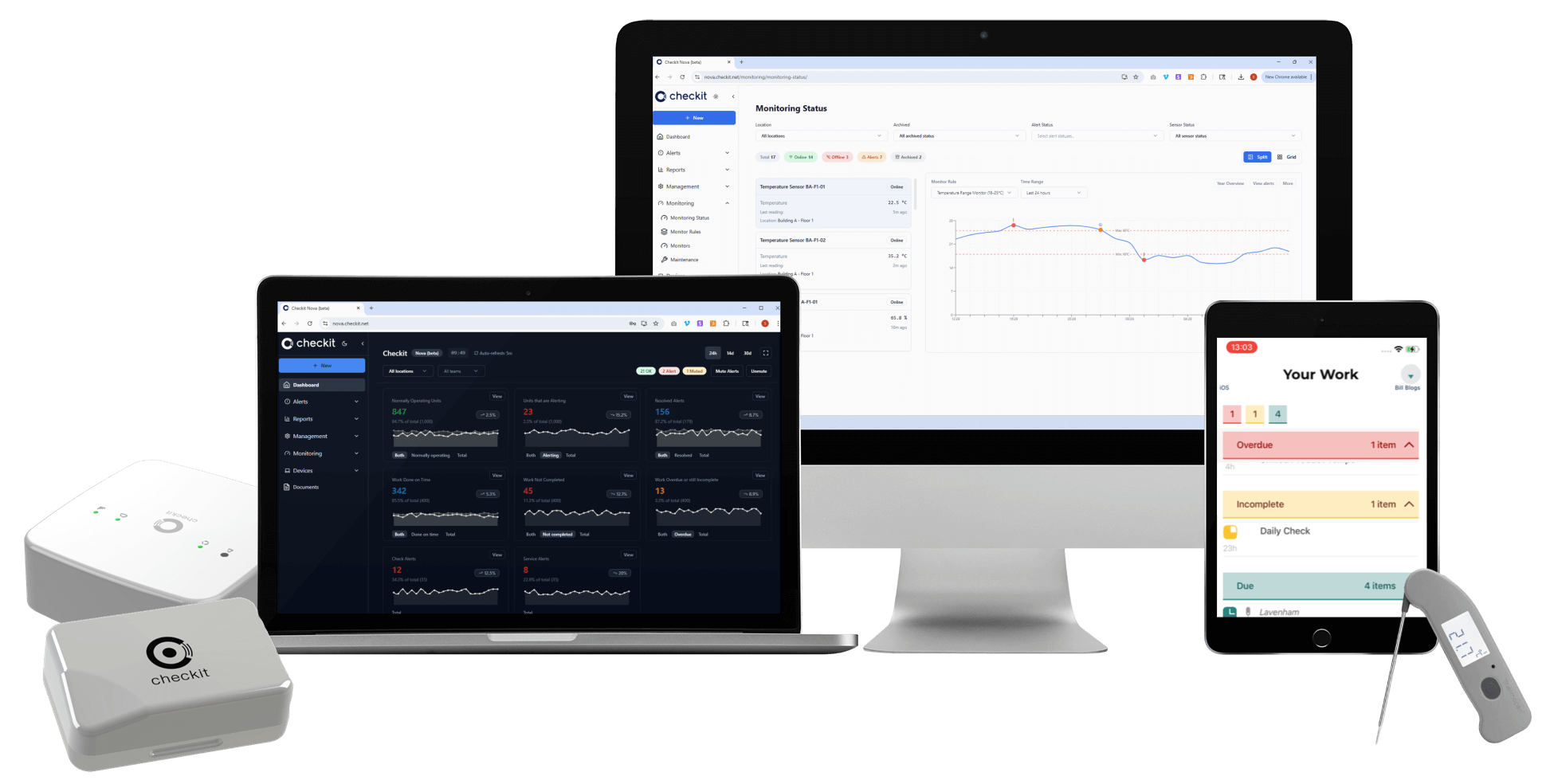

Checkit combines IoT sensors, mobile apps, and cloud analytics to deliver automated monitoring, streamlined operations, and complete visibility across all your locations.

Operational Non-Compliance & Waste

Manual processes, paper logs, and disconnected systems create compliance gaps, hidden waste, and operational blind spots that put your business at risk.

Paper-Based Processes

Manual logs are error-prone, easily falsified, and impossible to audit in real-time.

Unmonitored Equipment

Critical equipment fails silently. By the time someone notices, inventory is spoiled.

Audit Anxiety

Scrambling to find records before inspections. Missing signatures and incomplete logs.

Reactive Operations

Problems discovered after the damage is done. No early warning, no prevention.

Hidden Waste

Spoiled inventory, wasted labor hours, duplicate efforts. Costs accumulate invisibly.

Staff Time Drain

Hours spent on temperature logs and compliance paperwork that could be automated.

Sensors + Apps + Platform

Three integrated components that work together to deliver automated monitoring, streamlined operations, and complete visibility.

Sensors

Always-on monitoring

Wireless IoT sensors continuously monitor temperatures, humidity, and equipment status.

- Temperature sensors

- Door/open sensors

- Humidity monitoring

- Equipment alerts

Mobile Apps

Operations in your pocket

iOS and Android apps for task completion, alerts, and on-the-go visibility.

- Digital checklists

- Real-time alerts

- Photo capture

- Offline capable

Platform

Command center

Cloud dashboard for complete visibility across all locations. Reports and analytics.

- Multi-site dashboards

- Compliance reports

- Trend analytics

- Audit trails

How They Work Together

Sensors capture data automatically and send it to the cloud. Mobile apps alert staff to issues and guide them through tasks. The platform aggregates everything into dashboards, reports, and audit-ready documentation.

What Can You Measure?

Whether you can see it or not, we can measure it. Reduce waste, stay compliant, and improve your bottom line with intelligent monitoring.

Digitize Tasks & Workflows

Move off paper-based or manual tracking to a fully digital and mobile-ready solution.

Automate Temperature Monitoring

Capture temperature data in real-time, ensuring freezers, cold rooms, and labs stay within safe parameters.

Track Humidity

Protect assets, ensure product quality, and prevent mold, mildew, and equipment malfunction.

Measure O2 and CO2 Levels

Ensure safe oxygen levels in hospitals, laboratories, and industrial settings.

Predict Equipment Failures

Understand when freezers and fridges protecting your critical assets are likely to fail.

See Ambient Levels

Monitor temperature, humidity, light, and sound levels for comfort and safety.

Detect Water Leaks

Real-time alerts help you respond quickly to water leaks and minimize damage.

Much, Much More

Measure motion, levels, proximity, door openings, and so much more.

Driving Better Behavioral Change at Scale

Every feature we build drives toward three outcomes that matter most to operations leaders.

Safety

Protect people and products

Automated monitoring catches issues before they become incidents.

Compliance

Always audit-ready

Every check automatically documented with timestamps and digital signatures.

Visibility

See everything, everywhere

Real-time dashboards show compliance status across all locations.

Asset Intelligence

Unlock predictive insights and performance data for your freezers, fridges, and critical assets. Move beyond traditional monitoring to predict failures before they happen.

Be Proactive

Identify underperforming assets before costly failures

Optimize Assets

Extend asset life and replace only when necessary

Reduce Risk

Protect critical inventory from unexpected failures

Plan Confidently

Budget accurately with data-driven insights

How It Works

Connect Data to Checkit

Your sensors are already capturing real-time data

Turn On Asset Intelligence

AI/ML models analyze patterns and predict outcomes

Access Predictive Insights

Filterable dashboard highlights predictions and savings

“Asset Intelligence allows me to have a real plan in place of what is priority, what's costing the most to run, and what potentially needs new investment.”

Philip King, BWG Foods, Operations Development Manager

Industries We Serve

Each industry has unique challenges. Our solutions are tailored to meet the specific compliance, safety, and operational needs of your sector.

Senior Living

Compliance and resident safety for senior care communities

NHS Pharmacies

Connected automated monitoring for pharmaceutical compliance

Food Retail

Food safety for convenience stores and food-to-go

Food Facilities

Food service operations for venues and events

Medical

Compliance for plasma centers and labs

Operations

Operational compliance for restaurants and hospitality

Texas Tech & OVG Hospitality

Protecting Revenue & Guest Experience at Scale

“Within the first two months of using Checkit, the software paid for itself.”

Why Organizations Choose Checkit

Trusted by leading organizations across multiple industries to ensure compliance, safety, and operational excellence.

Multi-Site Control

One platform for all locations. Standardize and manage centrally.

Regulatory Compliance

Meet and exceed industry requirements with automated monitoring.

Operational Efficiency

Eliminate paper processes and free your teams to focus on what matters.

Audit-Ready Always

Complete digital records with full traceability. Be confident in every inspection.